By combining printing and laminating into a single process costly out of line individual processing is avoided and higher more efficient production is achieved.

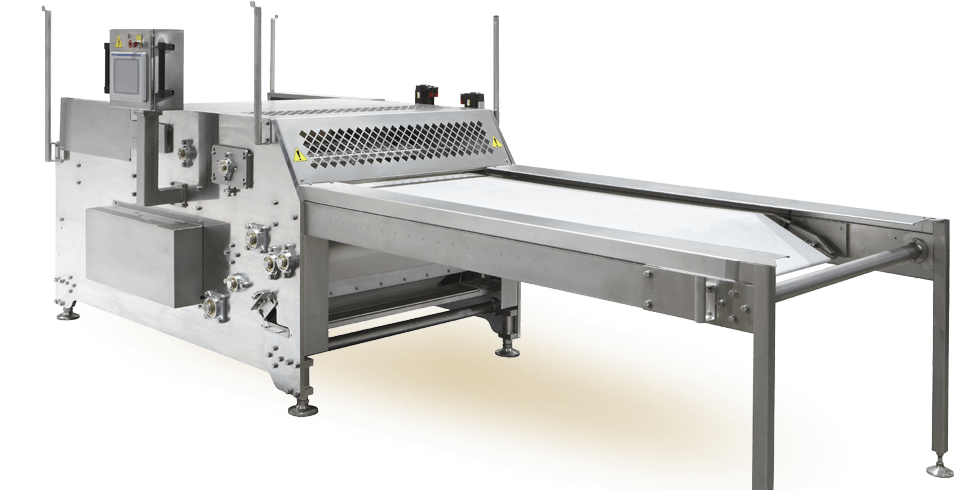

Inline lamination station.

We have designed our inline laminating stations and integrated them in the systems as a whole ourselves so far sml has now directly integrated the laminating station in the new plant which will again be a combination of an erema recycling system and an sml cast part.

32 78 lbs 14 9 kg lamination station 1 2 and impressor.

Produce food grade flexible packaging on narrow web flexo with this retrofit solution.

Call for quote 973 227 6995 the industry leader.

Cantilever design sleeve system on coating roller for quick change.

675 mm x 270 mm x 513 mm weight lamination station 1.

The combi model is a versatile machine combining a series of different coating and lamination techniques starting from the basic operation of dry and solventless lamination for either duplex or triplex lamination up to multi layer f lamination inline with different coating or printing process.

Adjustable available in 3 to 24 adjustable stations our machines enable ultimate flexibility in process design and material placement.

Up to multi layer f lamination inline with different coating or printing process.

29 92 lbs 13 6 kg lamination station 1 and 2.

This inline coater laminator station is designed to coat a secondary web laminate to the primary and finally deliver the web back to the companion equipment s existing rewind unit.

We understand completely the requirements in today s production environment the demands required.

Lamination station 1 2 and impressor dimensions.

Available on performance series presses.

36 96 lbs 16 8 kg.

Converting laminating ccd alignment inline printing rotary die cutting and laser cutting are all complete in this module.

Simple and inline laminators.

Chesnut engineering has over 50 years experience in the art of flexi print presses flexible packaging press inline lamination gravure presses and much more.

The compact smart camera design allows the register control cameras to be mounted in between print stations for faster corrections reducing startup waste by up to 50 75.

Expand your business opportunities by entering new markets hl500 is a high performance compact hot lamination system dedicated to the refining process in the production of high quality photo books book covers and photo prints.

The sl series solventless laminator is a member of our coating laminating line.