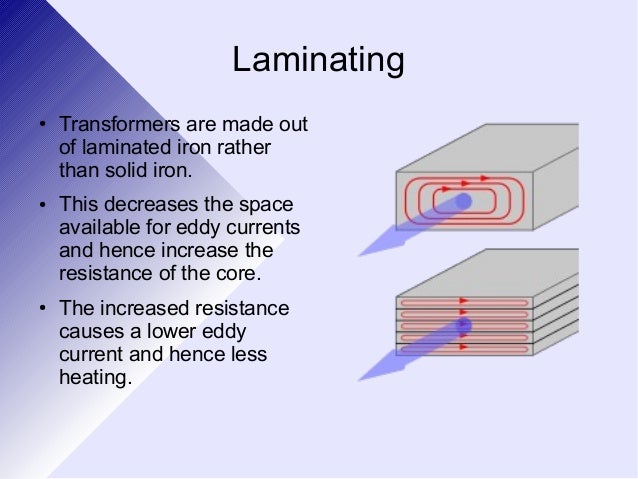

The core of the transformers needs to be laminated to reduce the eddy current that has arisen from the induced voltages through the core reducing the heat loss of the whole core which is why the core of the transformers is laminated to restrict the eddy currents flowing through it.

Iron core power transformer is laminated to reduce.

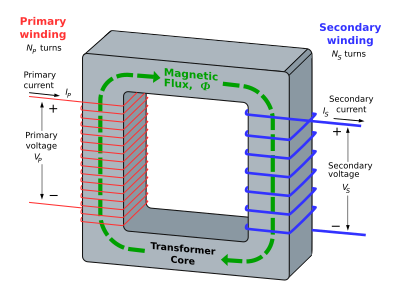

Provide support to windings.

Laminated transformer core the core of a laminated transformer consists of a stack of punched sheet alloy made of iron and nickel the laminations.

Eddy current is induced in core and circulates normal to the width of the core causing heat.

Power factors of both the transformers will be same.

A transformer core is laminated to a reduce hysteresis loss b reduce eddy current losses c reduce copper losses d reduce all above losses.

The purpose of providing an iron core in a transformer is to.

Question is a transformer core is laminated to options are a reduce hysteresis loss b reduce eddy current losses c reduce copper losses d reduce all above losses e leave your comments or download question paper.

The core is laminated to reduce these to a minimum as they interfere with the efficient transfer of energy from the primary coil to the secondary one.

The current flowing through the resistance of the metal heats it by joule heating causing significant power losses.

Eddy current losses are proportional to the frequency and magnitude of the current in the core of the transformer.

Laminating the iron core eddy current losses within a transformer core can not be eliminated completely but they can be greatly reduced and controlled by reducing the thickness of the steel core.

Therefore solid iron cores are not used in transformers or inductors they are replaced by laminated or powdered iron cores or nonconductive cores like ferrite.

The core is made from e and i lamination.

The eddy currents cause energy to be lost from the transformer as they heat up the core meaning that electrical energy is being wasted as unwanted heat energy.

Iron core is thin laminated in transformer to avoid the loss of eddy current.

The percentage of nickel is adjusted to give a reduced energy loss when the core is magnetised by the magnetic field produced when the primary winding is energised.